here nothing is impossible

An arc welding machine uses an electric current to create an arc between an electrode and the workpiece, melting and fusing the metal together.

The TIG welding machine uses a tungsten electrode to create an arc which produces high-quality and precise welds on various materials.

The MIG welding machine uses a continuously feeding wire electrode and a shielding gas to join two pieces of metal together.

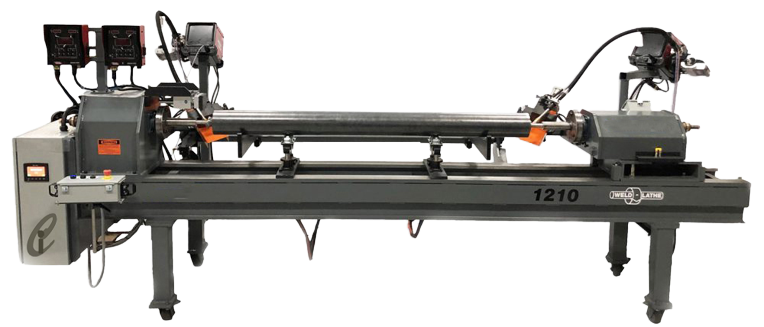

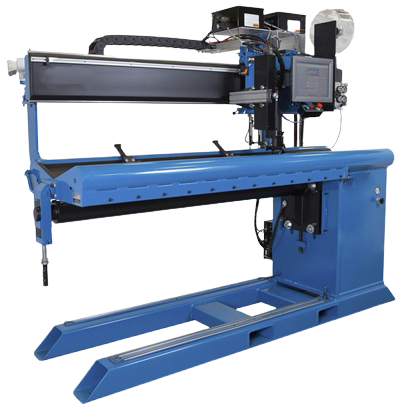

The auto welding machine automatically joins two pieces of metal together using an electric arc and filler material.

It is a type of automated welding equipment that uses a linear motion system to move the welding torch along a straight path, allowing for efficient and precise welding of long, straight seams.

A mobile crane is a type of crane that is mounted on a mobile platform, such as a truck or a crawler. It can lift heavy loads to great heights with ease.

An EOT (Electric Overhead Traveling) crane is versatile, efficient, and offer a safe and reliable method for lifting and transporting materials in a variety of settings.

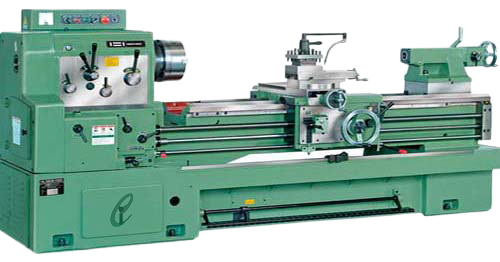

A lathe machine is a tool used for shaping and cutting various materials by rotating them against a cutting tool.

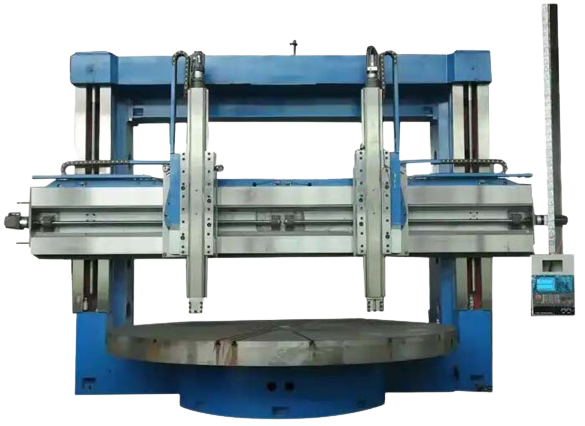

It is used for turning and shaping large, heavy workpieces such as metal plates, pipes, and shafts, by rotating them on a vertical axis while cutting tools shape the material.

The drilling machine is a versatile tool that is used to create holes in various materials, such as metal, wood, and plastic.

The radial drilling machine is a versatile tool used for drilling holes of various sizes and depths in a variety of materials.

The tapping machine automatically creates threaded holes by rapidly tapping a rotating drill bit into the material.

It is a versatile tool that can precisely cut and punch holes in metal angle channels for various construction and fabrication projects.

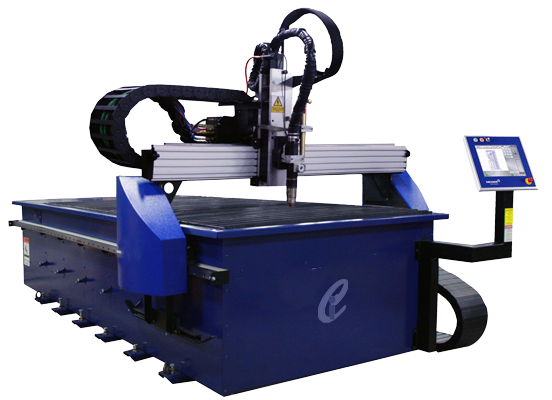

To cut metal sheets at various angles. It utilizes computer numerical control (CNC) technology to produce intricate cuts with speed and accuracy.

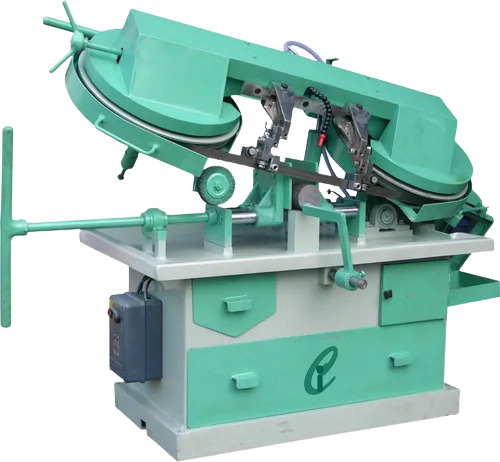

Band saw cutting machine works by using a continuous band blade that rotates around two wheels to make precise and accurate cuts.

A sheet rolling machine is a device used in manufacturing and metalworking processes to roll sheets or plates of metal into cylindrical, conical, or other curved shapes.

It is used to shape and bend metal sections, such as I-beams, U-channels, angles, and flat bars. It consists of a set of rollers that can be adjusted to produce the desired shape and size of the metal section.

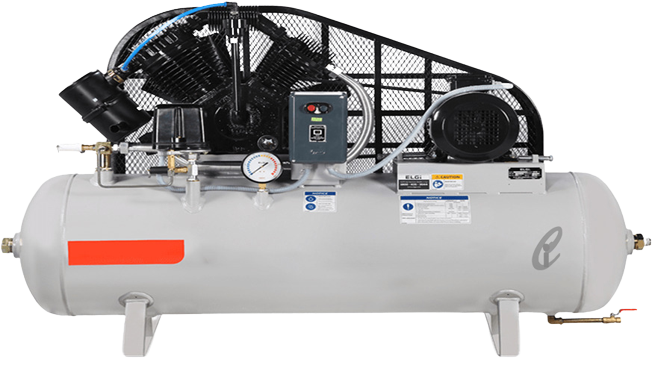

Probably the most common use of air compressors in everyday life, refrigerators, freezers and air conditioners all use air compressors to chill the air.

Generators are useful appliances that supply electrical power during a power outage and prevent discontinuity of daily activities or disruption of business operations.

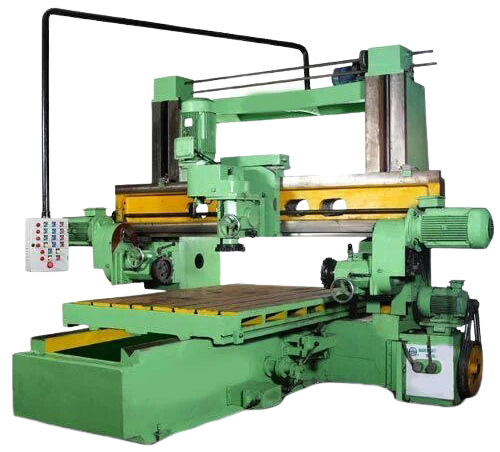

The HMT milling machine is designed to perform various machining operations such as drilling, cutting, and shaping of materials.

To either vertical or horizontal, are usually used to machine flat and irregularly shaped surfaces and can be used to drill, bore, and cut gears, threads, and slots.

A grinding machine is a machine tool equipped with an abrasive wheel used for producing fine finishes or making light cuts on metals and other materials.

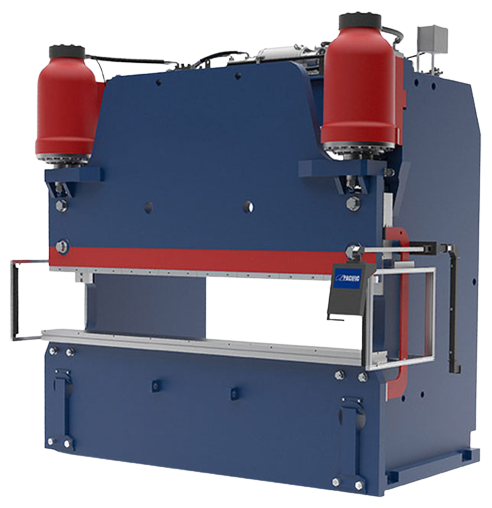

A press brake is a piece of manufacturing equipment that is used to bend sheet metal. A press brake is typically narrow and long so that large pieces of sheet metal can be bent by it.

Integrated systems and construction allow for repeatable and accurate bending within .002" under full load.

Shearing machines are multipurpose devices used in the cutting of alloys and other sheet metal. Some shearing machines use a scissor-like, angular shear action to cut metal into sheets or strips.

Nibbling Machine is a rugged, sturdy & reliable multipurpose machine capable of many sheet cutting & forming operations. It is cold-cutting process which uses a punch to cut multiple holes in the workpiece.

It is an oil pump that transports hydraulic oil to the integrated cartridge valve block. The hydraulic oil is distributed to the upper or lower chamber of the cylinder through each check valve and relief valve, and the cylinder is moved by the high-pressure oil.